|

|

|||

|

Modified First flush diverter drawing (tested 2010-01-05)

This modified version has been tested and has shown it will reduce the level of total petroleum hydrocarbons from 3.9 mg/L to less than 1 mg/L, and has been shown to reduce the total coliform count from 50,000 cfu/100ml to 30,000 cfu/100ml. The photographs on the right are shown for reference, since the only changes made are to the inside part of the diverter where the float seal device has been added.

Please note: the drawing below is a modified version of the non-float first flush diverter originally built and tested in 2008.

Back to slowsandfilter.org diverter page

This modified version has been tested and has shown it will reduce the level of total petroleum hydrocarbons from 3.9 mg/L to less than 1 mg/L, and has been shown to reduce the total coliform count from 50,000 cfu/100ml to 30,000 cfu/100ml. The photographs on the right are shown for reference, since the only changes made are to the inside part of the diverter where the float seal device has been added.

Please note: the drawing below is a modified version of the non-float first flush diverter originally built and tested in 2008.

Back to slowsandfilter.org diverter page

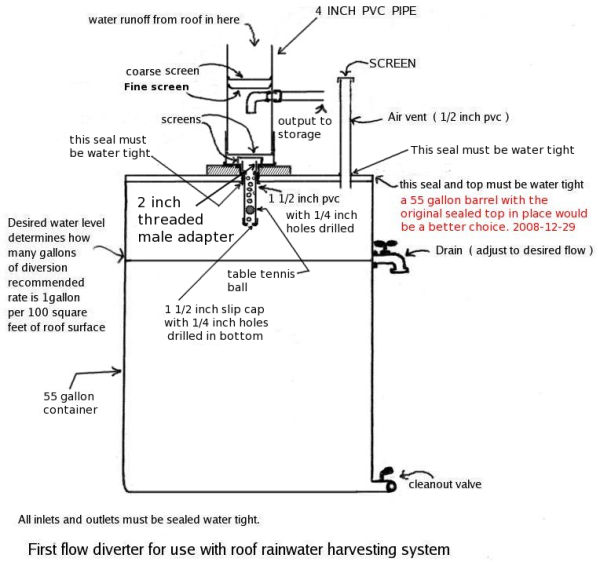

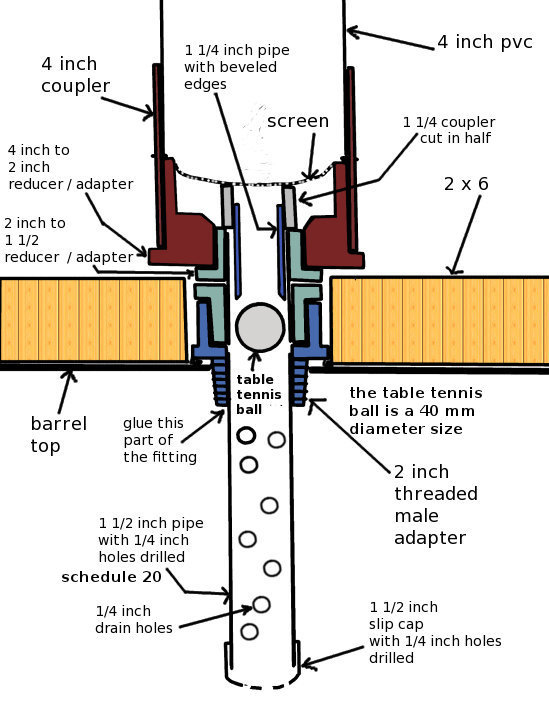

back to original diverter page Below is a picture and drawing of the float seal configuration using the slip cap, table tennis ball and threaded male adapter.   The idea of a first flush diverter is to keep the most polluted flow of water out of a rain water harvesting system. Dust, organic material, bacteria and air pollution particles build up on a roof surface during a dry spell. The first flow from rain after a dry spell will contain concentrated poisons dissolved in the rainwater as it flows across the roof surface. A first flush diverter prevents the first 15 or 20 gallons of toxic water from entering the storage system by diverting it into a temporary holding area and then allowing only the cleaner water to flow into the storage system. The recommended minimum amount of diversion is 1 gallon per 100 square feet of roof surface - this diverter is set for about 2 gallons per 100 square feet. How it works: Watch a demonstration of the diverter on YouTube here: Water from the downspout enters the 4 inch pvc pipe and flows directly into the 55 gallon container through the 1 1/2 inch pipe drilled with 1/4 inch holes. As the pre-set space in the 55 gallon container fills; the air vent allows the air inside to escape while the water flowing in displaces it and the table tennis ball floats on the top of the surface of the water. If there were no vent much of the water would back up and flow into the system before the barrel filled completely during moderate rain-fall events. When the 15 gallon space in the barrel becomes full, the table tennis ball floats to the top and seals off the opening into the barrell. The water then fills the 4 inch pvc pipe on top until it flows out the pipe on the side. As long as the air vent is higher than the outlet; water will flow out the side pipe. If the air vent leaks or is not "above" the water output the water will just flow out the vent. By the time 15 gallons of water has run off the roof most of the build-up of dust, and organic decaying matter has been washed off the roof surface and is held in the 55 gallon container. The faucet is set to drip slowly enough to allow the 55 gallon container to fill but also allow the 55 gallon container to empty after the rain stops. A 90 degree fitting attached to the output pipe pointing downward on the inside of the 4 inch pvc (added July 2008), keeps all of the first flush water out of the system. It would be a good idea to completely drain and clean out the 55 gallon container at least twice a year (easily done by opening the cleanout valve). All the input and output openings must be sealed or the device will leak. (You might ask why that silly looking air vent with the little hat-like thing on it? Do I really need that? The answer is yes you do. Since the barrell is air tight - without a vent in the top it won't fill correctly. The vent must be higher than your output or the water will simply pour out the vent and never even make it to your output pipe - and the air vent must be sealed where it goes into the wood top. Also a screen over the air vent is a must to keep out mosquitoes and larger objects that might plug it up.The thing works and works well - and its disgard flow rate is easily adjustable.) It has no moving parts (exept the faucet) and nothing to wear out except the screens - if they are stainless steel they will last many years. Set the faucet to drip slowly enough to allow the water to empty between rain periods. I set the rate by watching the water drip out of the downspout after the rain had stopped and the flow from the downspout was typical of what occurs during a very light drizzle, and then set the faucet to approximately the same "drip" rate. In 3 or four days the water level in the 50 gallon container will be down 15 gallons. When any significant rainfall occurs 15 gallons of water will be discarded before any enters the filter with this design. If there is only a light drizzle which is not enough to "wash" the roof none of the water goes into the filter, you don't want it anyway because it has roof chemicals and dissolved dust in it. Where you put the drain faucet will determine how much water is discarded before it is allowed to enter the filter system. If you want to use the disgarded roof water for utility purposes like washing your car or outdoor cleaning you can have the faucet drain into a small container that allows the excess water to fill another storage container. This design is adapted to the rainfall in this area which is usually not concentrated and heavy, but light and continuous. If you live in an area where there are periods of very heavy rainfall, you will probably want to include an overflow pipe on the 4 inch input, otherwise the water will flow over the top of the diverter. Also the ouput to your filter or temporary storage may need to be a larger diameter than what is shown in the pictures above.At first, I used a recycled container and built the top from cedar scraps. (2009-08-25) A different barrel with a sealed top is now being used. The silicone seal is not easy to keep tight as the wood expands and contracts with varying moisture content and the silicon has cracked several times, and in freezing weather the entire wood top has been broken loose. Cleaning out the screens takes about 5 minutes, and with a drain on the bottom the inside of the barrel can also be cleaned out and all you have to do is open the faucet on the very bottom and let it drain till it is empty - all the muck inside drains out the bottom. back to original diverter page  First flow diverter picture. New (as of Nov.11 2009): The output pipe has been changed to inch-and-a-half pipe, instead of 3/4 inch pipe. The diverter will now accept up to 24 liters per minute without overflowing. back to original diverter page |

|

Inside view of the 4 inch pvc  Inside view of the 4 inch pvc with 90 degree fitting and screens installed (the 4 inch pvc can be filled with pea gravel but it is more difficult to clean) Below is shown how to convert a 55 gallon barrel (with a top already included) into a first flush diverter:  The container must be air tight (water tight - make sure the two original threaded caps are sealed tightly - wrap the threads with plumbers tape and tighten them down securely). Use a pvc male adapter for the water input IMPORTANT NOTE: (a 1 1/4 inch adapter is shown here but a 2 inch pvc threaded male adapter with a reducer-adapter has been used in the modified version - see the drawing shown on this page). The size of the hole saw must be increased to 2 1/4 inch to match the threads of the larger 2 inch male adapter. The "o" ring is there to provide a seal. Also use "teflon tape" often called "plumbers tape" to seal the threads on the adapter.  The hole may need to be slightly enlarged to make the pvc male adapter "thread" into the hole. This is a bit tricky. Try threading the adapter first. I used the "fine" section of a half-round wood rasp to SLIGHTLY enlarge the hole after drilling it with the hole saw. If you have ever used a tap you will understand that the pilot hole cannot be too big or the whole thing is ruined. Take it slow and only file a very slight amount. It will take some forceful pushing to tap the plastic hole with the pvc adapter but it does work. Be careful so the file is not dropped into the barrel!  This shows the adapter installed. Make sure it is tight. The 4 inch pvc assembly shown in the wood top version is used here. Connect it with 1 1/2 inch pvc pipe and a reducer-adapter. I would suggest gluing one of the connections between the input and the pvc adapter.  This shows the input (the same input that is shown in the wood top version) installed with a 2X6 support between the base and the top of the barrel. The vent is installed using a 1/2 inch male adapter and the hole to thread that in is drilled with a 3/4 inch spade bit. The drain faucet is installed the same way the vent is installed. The 3/4 inch spade bit drills a hole just the right size to "tap" the threads of a 1/2 inch faucet into the plastic barrel. Be sure to use an o ring washer and plumbers tape to insure a good seal. I have tested this and it works. The output on the side of the 4 inch pvc should be several inches higher if used in areas where very heavy rainfall occurs - and remember that the vent must be higher than the output. Be sure the diverter is drained if freezing weather is anticipated |

||

|

|

This work is licensed under a Creative Commons Attribution-ShareAlike 2.5 License. terms of use